Swing Lip

The ZEUS <=> HANDLING dock leveller is designed to carry the load and produced to your exact requirements and fully compliant with European regulations BSEN1398. Our bespoke swing lip dock leveller can be manufactured to suit any new or existing formed pit. We produce the following configurations: standard pit type, suspended frame type, cast in concrete type and also a free standing version.

Features include hydraulic hose break cartridge, Integral safety prop, Integral toe guards, and hazard marking to sides of platform. The platform deck is designed to flex laterally by 100mm to cater for uneven trailer canter whilst retaining its integrity.

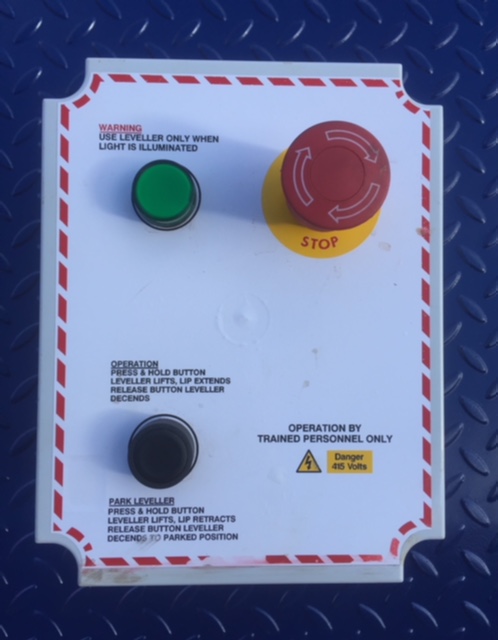

The ZEUS <=> HANDLING electro/hydraulic swing lip dock leveller is powered by a motor rated between 0.75 and 1.1 Kw dependent on size of dock leveller, requiring a power supply of 415v 3 Phase and Earth.

The control voltage is 24v via a transformer installed in the wall mounted control panel which has a IP55 rating.

Deck Construction

The ZEUS <=> HANDLING deck system is manufactured with 6/8mm steel chequer plate with ten folded longitude steel sections to strengthen deck, using the folded steel sections allows the deck to flex by 100mm to cater for uneven parked trailers but does not affect stability of the platform.

Lip Construction

The ZEUS <=> HANDLING dock leveller lip system is manufactured with 12.5mm chequer plate with either ten self clean hinge units or piano style hinge assembly. The lip plate can be machined with a 7 degree bend or can be supplied straight, the lip plate has a 50mm machined leading edge for smooth transition from leveller to trailer.

Base Frame Construction

The ZEUS <=> HANDLING base frames are manufactured in three configurations;

Standard pit mounted type: Where the dock leveller is installed into a prefabricated concrete pit with steel kerb angle sections in place, The dock leveller sits on the pit floor and is welded to rear and front sections.

Suspended type: Where the dock leveller is installed on top of the pre-installed concrete pit with recess kerb angle set. As the name suggest this system is used where tail lifts are used to allow a recess to the underside of dock leveller to stow tail lift.

Cast in type: Where the dock leveller is placed onto a flat pit floor and fixed then concrete is poured around the dock leveller, the leveller is supplied with a cable lance so is ready to operate when civil works are complete, kerb angle sets are not required for this configuration.

Operation

When the operation button is pressed the deck will rise until the full height is reached at this point the swing lip will be activated, when the swing lip is fully extended the operation button can now be released allowing the deck to descend onto the parked trailer. The deck will move vertically up and down with the trailer movement in its float mode. Following the loading/unloading has taken place to park the dock leveller into its ready state the operation button is to be depressed this will activate the deck to rise and to retract the swing lip, when lip is fully retracted the operation button can be released this will allow the deck to descend to its parked ready state.

Optional features

> Tapered Lip > Different Lip Sizes > Base Frame Emergency Stop > Load Capacity > Colour Matching

> Galvanised Finish > Insulated Deck > Anti-slip finish > Integrated control system > Robust Construction > Fully compliant with BSEN 1398 > Full range of sizes and load capacities available > 6000kg or 9000kg standard capacities.